While the Alpha 4 firmware is still the baseline, A5 introduced some major changes to the case design. These optimizations include an over-the-top lid instead of an inset, making it tougher overall, easier to print and a cleaner appearance.

Internal case optimization also results in fewer wires, thus less compression on assembly. This makes the Cipherpod Zero prettier, so I’ve made a couple and indeed, they look great.

I’ve also discovered that PETG is supposed to be optimal for RFID transmission but it’s not, PLA still works best. Also, Carbon Fiber is conductive so it messes with the touchpad keyboard. If you use PLA-based Carbon Fiber with a transparent PLA layer underneath, it IS possible to create a carbon fiber case, which I’ve successfully made (the red case in the article photo is red-dye CF). These experiments show that when manufacturing, the type of plastic we choose alongside RFID antenna choice absolutely matters.

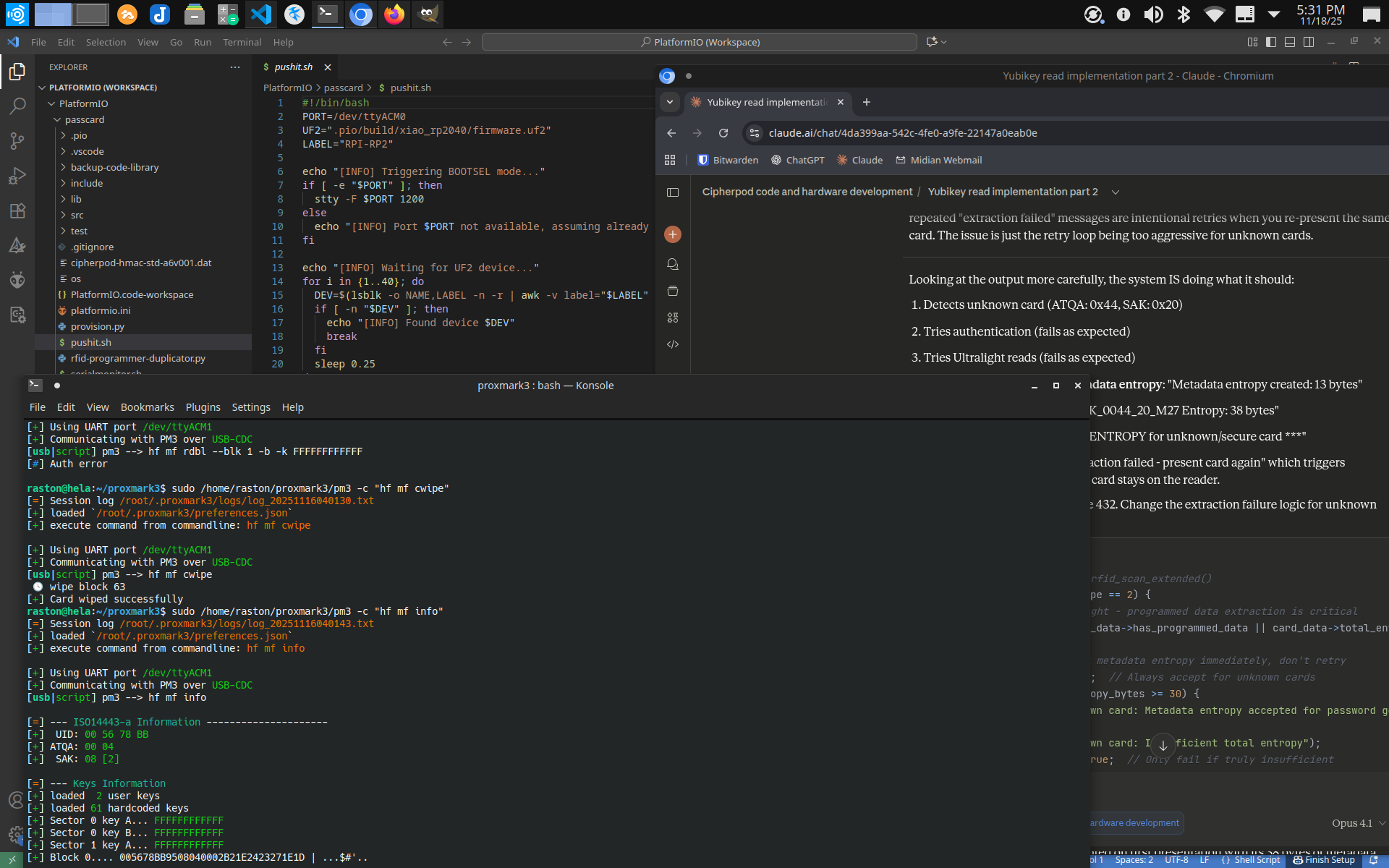

I’ve also taken the time to write an RFID programmer making it easier to create and duplicate RFID tokens. This also makes it easier to set known values for testing Chi-Square elements to confirm they’re working right.

Both the programmer and CPod now natively work with MiFare, Ultralight and NDEF RFID devices, not only working more reliably for all, but allowing us to resell smaller RFID fobs, different key cards and even RFID smartrings, such as those found here:

https://duckduckgo.com/?t=ffab&q=rfid+smartring&ia=images&iax=images